PERMANENT MAGNETIC DRAWERS SEPARATOR for iron separation

Magnestic FILTRATION

Get In Touch

DRAWER MAGNETIC SEPARATOR,DRAWER MAGNETS:

Perfect for removing small ferrous contaminants from a variety of dry, free-flowing products!

Magnetic Drawers, also known as Drawer Magnets, where the power of magnetic grates and housing come together to form an innovative solution for removing medium and fine ferrous contaminants from a range of dry free-flowing products. Magnetic drawers, or drawer magnets, are commonly used in the food and chemical industries due to their exceptional ability to capture tramp metal.

The magnetic drawers are constructed with a group of magnetic grates and housing and can be installed into the pipeline in either one layer or multiple layers, depending on the material condition. The mounting way of the drawers is left to the discretion of the customer, so it can be customized to fit their unique needs.

Magnetic drawers are an ideal solution for capturing medium and fine ferrous contaminants from dry free-flowing products. With their customizable features and easy cleaning process, they are a must-have for any food or chemical industry looking to ensure the purity of their products.

We’re committed to delivering high-quality Magnetic Drawers to our customers. If you have any queries or would like to place an order, don’t hesitate to contact us. We’re always here to help.

The ADVANTAGE of

DRAWER TYPE MAGNETIC SEPARATORS

1. Improved Efficiency:

– Quickly and easily remove ferrous metal contaminants from dry free-flowing materials.

– Reduce downtime for cleaning and maintenance.

– Increase productivity by minimizing product contamination.

This means you can enjoy improved efficiency and enhanced product quality!

2. Improved Product Quality:

– Protect downstream equipment from damage caused by metal fragments.

– Ensure product purity and meet quality standards.

By doing this, we can improve customer satisfaction by delivering a cleaner and safer product.

3. Cost Savings:

– To reduce material waste, let’s make sure we remove contaminants before they enter the production process.

– We can also minimize equipment wear and tear to extend its lifespan.

– Additionally, we can simplify cleaning procedures to lower maintenance costs.

4. Versatility:

– Our product is designed to be adaptable to different production lines and material handling systems.

-We offer various sizes and configurations to meet your specific needs.

5. Easy Installation and Maintenance:

– It’s easy to install and integrate into your existing systems.

– This product requires minimal maintenance, which means less downtime and lower labor costs for you.

– Plus, its durable construction ensures long-lasting performance, so you can rely on it for years to come.

6. Environmentally Friendly:

It’s environmentally friendly, so you can feel good about reducing waste and promoting sustainable practices for a cleaner and safer environment.

Drawer type magnetic separators are a cost-effective and efficient solution for removing ferrous metal contaminants from dry, free-flowing materials. This leads to improved product quality, increased efficiency, and enhanced safety.

Why us

REASON TO CHOOSE SINONEO MAGNETic drawers

Quality products

You’re going to love our services! We guarantee 100% quality and the best customer experience. You’ll receive exactly what you’re looking for!

WORLDWIDE SHIPPING

We will help you find the most cost-effective shipping options worldwide that making your shipping experience as friendly and hassle-free as possible.

Custom Design Services

We offer magnetic drawer separator that can be customized to meet your unique needs for any operation!

On Time In Progres

We can deliver customized drawer magnetic separator within weeks, not months. This will save you both time and money!

Get a free Custom Quote for your BUSINESS now!

Our friendly magnet engineers are here to help you get exactly what you need for retail or industrial purposes, with super high quality & a competitive price.

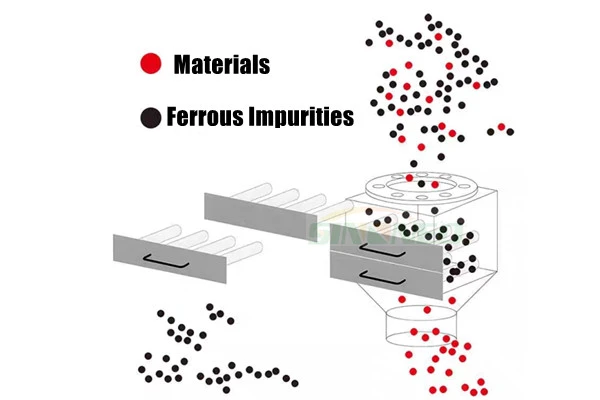

THE WORKING PRINCIPLE.

How do the drawer magnets work?

They operate using the incredible power of magnetic attraction and field orientation.

Drawer magnets are amazing! The working mechanism is easy, it involves the following steps:

1. Material Flow: The material flows through a housing or drawer unit that contains one or more magnetic tubes or grids.

2. Magnetic Tubes/Grids: The housing or drawer unit contains high-intensity magnetic tubes or grids. These tubes/grids are equipped with powerful rare-earth magnets, such as neodymium (NdFeB) magnets, which generate a strong magnetic field.

3. Magnetic Attraction: As the material flows through the drawer magnet, any ferrous contaminants in the material are attracted to the surface of the magnetic tubes or grids due to the strong magnetic field.

4. Contaminant Capture: The ferrous contaminants adhere to the surface of the magnetic tubes or grids, preventing them from passing through the drawer and entering downstream equipment.

5. Cleaning or Maintenance: Periodically, the drawer magnet needs to be cleaned or maintained to remove the accumulated contaminants from the magnetic tubes or grids. This can be done by manually removing the drawer and cleaning the tubes/grids or through automated cleaning mechanisms, such as pneumatic or mechanical systems.

Drawer magnets are a great option for dry or free-flowing materials, but keep in mind that they should not be used for liquids or materials with high moisture content.

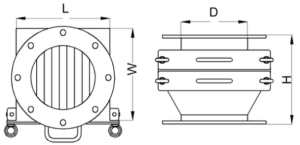

The Main Type of

PERMANENT DRAWER magnets SEPARATOR

| Item No. | Size(mm) | No. of rods | |||

| D | H | L | W | ||

| SMDM150 | 159 | 300 | 208 | 205 | 5 |

| SMDM200 | 219 | 300 | 258 | 255 | 7 |

| SMDM250 | 273 | 300 | 308 | 305 | 9 |

| SMDM300 | 325 | 300 | 358 | 355 | 11 |

| SMDM150 | 159 | 230 | 208 | 205 | 4 |

| SMDM200 | 219 | 230 | 258 | 255 | 5 |

| SMDM250 | 273 | 230 | 308 | 305 | 6 |

| SMDM300 | 325 | 230 | 358 | 355 | 7 |

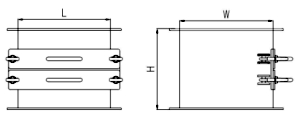

| Item No. | Size(mm) | No. of rods | ||

| H | L | W | ||

| SMDM2020 | 270 | 208 | 205 | 5 |

| SMDM2525 | 270 | 258 | 255 | 7 |

| SMDM3030 | 270 | 308 | 305 | 9 |

| SMDM3535 | 270 | 358 | 355 | 11 |

| SMDM4040 | 270 | 408 | 405 | 13 |

| SMDM5050 | 270 | 508 | 505 | 17 |

| SMDM2020 | 200 | 208 | 205 | 4 |

| SMDM2525 | 200 | 208 | 255 | 5 |

| SMDM3030 | 200 | 308 | 305 | 6 |

| SMDM3535 | 200 | 358 | 355 | 7 |

| SMDM4040 | 200 | 408 | 405 | 8 |

| SMDM5050 | 200 | 508 | 505 | 10 |

Optional Features for Magnetic Drawers:

1. Frames and Housing Material:

– SS304: Standard stainless steel suitable for most applications.

– SS316: More corrosion-resistant stainless steel for harsh environments.

– SS316L: Low-carbon version of SS316 for specific applications.

2. Surface Finishing:

– Fine Polishing: Smooth and glossy finish for easy cleaning.

– Dull Polish: Matte finish for a less reflective appearance.

– Sandblasting: Rougher finish for increased grip.

3. Magnetic Strength:

– 3000Gs: Suitable for light-duty applications.

– 8000Gs: Standard strength for most applications.

– 10000Gs: High-strength for heavy-duty applications.

– 12000Gs: Extra-high strength for demanding applications.

4. Working Temperature:

– <80°C: Suitable for standard temperature environments.

– 100°C: For environments with moderate heat.

– 120°C: For high-temperature applications.

– 150°C, 180°C, 200°C: For extreme temperature environments.

5. Type of Mounting:

– Round or Square: Standard mounting options.

– Flange: Provides additional stability for heavier loads.

– Quick-Release Clamp: Allows for easy removal and repositioning.

6. Designs:

– Easy Clean Type: Features smooth surfaces for effortless cleaning.

– One Layer: Basic design with a single magnetic layer.

– Multilayer: Multiple magnetic layers for increased holding power.

These optional features allow you to customize your magnetic drawers to meet your specific needs and requirements.

HAVEN’T FIND WHAT ARE YOU LOOKING FOR?

If you have not yet found what you are looking for then you can simply click “CONTACT US” for expert technical advice.Sinoneo is the professional magnetic drawers, drawer magnets manufacturer and supplier in China. Our magnet engineers will help you get exactly what you need – for your retail or industrial applications – in a short time with high quality at a better price.

FEATURED TYPE OF DRAWER MAGNETS

GET YOUR MAGNETIC DRAWER FILTERS TODAY!

Three Layer Drawer Magnets Separators

Permanent Magnetic Drawer Separator

Neodymium Drawer Magnets Separator

MAGNETIC DRAWERS FILTER

Drawer Magnets for Magnetic Separation

Heavy Duty Magnetic Drawer Separator

Don’t let metal contamination compromise your production process. Invest in our Drawer Magnets today and enjoy peace of mind knowing that your equipment is protected and your products meet the highest quality standards. Say goodbye to metal contamination headaches with our reliable and effective solution.

Faq

Read The FAQ’s

What materials are compatible with the drawer magnet?

Magnetic drawers work best with dry, free-flowing materials that contain ferrous metals like iron, steel, and nickel. They are not effective for wet or sticky materials or those that are highly magnetic.

Is the drawer customizable in terms of size or configuration?

We can provide you with customization options to personalize your magnetic drawers! You can make adjustments to the size and configuration to perfectly suit your needs. Let’s create the perfect drawer together!

How to clean the drawer magnetic separators?

Cleaning the magnetic drawers periodically is crucial for optimal performance. To clean the magnetic tubes, release the latch first and open the door. Remove the grate assemblies one at a time and remove the tramp metal by hand with cotton gloves or a duster. It is important to use extreme caution and wear gloves during the process to avoid any injuries.

How can I get a free custom quote?

Simply share these deets with us:

#1 What’s the material like?

#2 How strong do you need the magnet to be (measured in Gauss)?

#3 Tell us about the size and how you plan to connect it.

#4 What’s the working temperature?

#5 How many do you need?

You can send us an email, ring us up, or drop us a message on WhatsApp. Once we’ve got your info, expect a personalized quote in your inbox within 24 hours.

Got queries or need help choosing the perfect drawer magnet? Don’t hesitate to reach out! We’re here to assist you in finding the ideal drawer magnets for your needs.