SINTERED NDFEB MAGNETS: The most powerful and advanced permanent magnets available

RARE EARTH NDFEB MAGNETS:

THE ULTIMATE SOLUTION FOR HIGH-PERFORMANCE APPLICATIONS

Are you tired of struggling with magnets that can’t deliver the strength and reliability you need for your high-performance applications? Look no further than NdFeB magnets.

Sintered NdFeB (Neodymium Iron Boron) magnets are the most powerful permanent magnets available on the market today, delivering exceptional magnetic performance across a range of industrial applications. Thanks to their high magnetic energy product, coercive force, and maximum energy density, sintered NdFeB magnets are a popular choice for applications where high performance and reliability are essential.

Sintered NdFeB magnets, also known as sintered neodymium-iron-boron magnets, are a type of permanent magnet made from an alloy of neodymium, iron, and boron. The term “sintered” refers to the manufacturing process used to create these magnets.

Sintered rare earth neodymium magnets are known for their high maximum energy product (BHmax), which is a measure of the maximum magnetic energy that can be stored in a magnet. This makes them the strongest type of permanent magnet commercially available and suitable for applications that require a strong, compact, and reliable magnetic source.

THE Advantages of

sintered rare earth Ndfeb magnets

Neodymium magnets, often referred to as NdFeB magnets when combined with iron and boron, are known for their strong magnetic properties and have a wide range of benefits that make them a popular choice for various applications. Here are some key benefits of neodymium magnets:

1. Exceptional Magnetic Performance:

Sintered NdFeB magnets are known for their exceptional magnetic performance and can deliver the strongest magnetic field among all magnet materials. This makes them highly effective in applications that require strong magnetic forces.

2. High Resistance to Demagnetization:

Sintered neodymium magnets have a high resistance to demagnetization, meaning they can maintain their magnetic properties over time. This makes them reliable and long-lasting in various applications.

3. High Curie Temperature:

Rare earth NdFeB magnets have a high Curie temperature, which refers to the temperature at which a magnet loses its magnetic properties. Sintered NdFeB magnets can withstand high temperatures without losing their magnetic strength. This makes them suitable for applications that involve high temperatures.

4. Compact Size and Superior Strength:

Neodymium magnets can deliver the same performance as larger magnets while taking up less space. This makes them ideal for applications where size and weight are a concern, such as in portable devices or miniature motors.

5. Cost-Effective:

Despite being made from rare earth elements, the production process and the small size needed for many applications make neodymium magnets a cost-effective choice for high-performance requirements.

6. Environmentally Friendly:

Neodymium is a relatively abundant element, and neodymium magnets can be recycled. Neodymium magnets are often used in applications that contribute to energy efficiency and renewable energy technologies, such as wind turbines and electric vehicles, which can help reduce overall environmental impact.

7. Versatile Applications:

Versatile Applications: Sintered NdFeB magnets are widely used in various industries and applications, including automotive and aerospace engineering, wind turbines, medical devices, and more. Their superior magnetic properties make them suitable for demanding applications that require strong and reliable magnets.

8. Customizability:

They can be manufactured in various shapes and sizes to fit specific design requirements, offering design flexibility.

Overall, neodymium magnets offer a unique combination of high magnetic strength, compact size, weight efficiency, temperature resistance, versatility, and cost-effectiveness. These benefits make them a valuable choice for a wide range of applications across various industries.

It’s important to note that while neodymium magnets have many benefits, they also have some drawbacks, such as being brittle and susceptible to corrosion, which means they often require protective coatings or sealing to maintain their performance in various environments.

And the potential risk of personal injury or damage to equipment due to their extremely strong magnetic force. When working with neodymium magnets, it’s crucial to follow proper safety guidelines and consult with experts for specific application requirements.

Why us

REASON TO CHOOSE SINONEO FOR NEODYMIUM MAGNETS?

The highest quality Assurance

Our rare earth neodymium magnets are manufactured to the highest standards, ensuring that they deliver the best possible performance and reliability.

Outstanding ServiceS

We provide excellent customer service, including quick responses to questions, efficient order processing, and after-sales support.

Extensive customization Service

To meet your specific application requirements, we can customize the size, shape and coating of the neodymium magnets.

saving

We will be at our customers’ disposal with short delivery time and competitive prices without any compromise on quality.

Get a free Quote for your BUSINESS now!

Contact Sinoneo today to learn more about how we can help you find the perfect Neo Magnets for your business. With our expertise and commitment to quality, you can trust us to provide you with the best magnetic solutions on the market.

THE APPLICATION OF

rare earth neodymium magnets

Renewable Energy

The wind energy sector relies on neodymium magnets in wind turbine generators to efficiently convert wind power into electricity. They are also used in some solar energy applications.

Medical Devices

Neodymium magnets are used in MRI scanners to create high-resolution images of internal body structures. They are used in some magnetic therapy devices.

Consumer Electronics

They are used in many electronic devices, such as headphones, speakers, and microphones, because they can create strong magnetic fields in small sizes. They are also used in hard disk drives and smartphones.

Automotive Industry

In electric and hybrid vehicles, neodymium magnets are used in the motors and generators to improve efficiency and reduce weight. They are also employed in various sensors and latching mechanisms.

Industrial and Manufacturing

These magnets are used in industrial equipment like motors, generators, and turbines. They are also used in magnetic separators and filters to remove ferrous contaminants from various materials.

INDUSTRIAL AUTOMATION

They are used in industrial automation because they have a strong magnetic force and are stable. They are used in different parts of industrial robots to improve their performance in automation tasks.

Neodymium magnets are essential in industries where high-strength, lightweight, and compact magnets are required. The versatility of these magnets has led to their use in ever-evolving applications as technology advances.For more information on neodymium iron born magnets and their potential applications, contact sinoneo magnets today.

The technical date sheet of

sintered neodymium magnets

| Size | Outer Diameter/Length | Inner diameter/Width | Thickness | |

| Maximum | 150mm | 50.00mm | |

| Minimum | 1mm | 0.50mm | ||

| Maximum | 200mm | 200mm | 50.00mm |

| Minimum | 0.5mm | 0.50mm | 0.50mm | |

| Maximum | 150mm | 140mm | 50.00mm |

| Minimum | 1.00mm | 0.60mm | 0.50mm | |

| Segment, Arc, and other irregular shapes can be made according to the customer’s samples or drawings. | |||

At our manufacturing facility, we understand that sometimes standard magnets may not fit the bill. That’s why we offer custom-shaped magnets to meet your unique needs. Whether it’s a segment, arc, or other irregular shapes, we can produce magnets according to your samples or drawings.

Our experienced engineers and skilled technicians will work with you to ensure that your custom-shaped magnets meet the highest quality standards. We utilize advanced manufacturing technology and equipment to produce magnets with precise shapes, dimensions, and magnetic properties.

No matter what your application requires, we can deliver custom-shaped magnets that perform to your exact specifications. From prototypes to high-volume production runs, we have the capacity and expertise to meet your needs.

Get in touch with us today to discuss your custom-shaped magnet needs. We are committed to delivering innovative solutions and exceptional service to our customers.

| Grade | Remanence | Magnetic Induction | Intrinsic Coercivity | Max Magnetic Energy Product | Maximum Working Temperature≤ | |||||||

| Br ( KG) | Br (T) | Hcb (KOe) | Hcb (KA/m) | Hcj (KOe) | Hcj (KA/m) | (BH)max(MGOe) | (BH)max(KJ/m³) | ℃ | ||||

| Max | Min | Max | Min | |||||||||

| N35 | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥12 | ≥960 | 37 | 33 | 295 | 263 | N | ≤80 |

| N38 | ≥12.3 | ≥1.23 | ≥10.8 | ≥860 | ≥12 | ≥960 | 39 | 36 | 310 | 287 | ||

| N40 | ≥12.7 | ≥1.27 | ≥11.0 | ≥876 | ≥12 | ≥960 | 41 | 38 | 327 | 302 | ||

| N42 | ≥13.0 | ≥1.30 | ≥11.0 | ≥876 | ≥12 | ≥960 | 43 | 40 | 343 | 320 | ||

| N45 | ≥13.3 | ≥1.33 | ≥11.0 | ≥876 | ≥12 | ≥960 | 46 | 42 | 366 | 335 | ||

| N48 | ≥13.7 | ≥1.37 | ≥10.5 | ≥836 | ≥12 | ≥960 | 49 | 45 | 390 | 358 | ||

| N50 | ≥14.0 | ≥1.40 | ≥10.5 | ≥836 | ≥12 | ≥960 | 51 | 47 | 406 | 374 | ||

| N52 | ≥14.2 | ≥1.42 | ≥10.5 | ≥836 | ≥12 | ≥960 | 53 | 49 | 422 | 390 | ||

| N54 | ≥14.4 | ≥1.44 | ≥10.5 | ≥836 | ≥11 | ≥876 | 55 | 51 | 438 | 406 | ||

| N35M | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥14 | ≥1114 | 37 | 33 | 295 | 263 | M | ≤100 |

| N38M | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥14 | ≥1114 | 39 | 36 | 310 | 287 | ||

| N40M | ≥12.7 | ≥1.27 | ≥11.5 | ≥915 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ||

| N42M | ≥13.0 | ≥1.30 | ≥11.8 | ≥939 | ≥14 | ≥1114 | 43 | 40 | 343 | 320 | ||

| N45M | ≥13.3 | ≥1.33 | ≥12.0 | ≥956 | ≥14 | ≥1114 | 46 | 42 | 366 | 335 | ||

| N48M | ≥13.7 | ≥1.37 | ≥12.2 | ≥972 | ≥14 | ≥1114 | 49 | 45 | 390 | 358 | ||

| N50M | ≥14.0 | ≥1.40 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 51 | 47 | 406 | 374 | ||

| N52M | ≥14.2 | ≥1.42 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 53 | 49 | 422 | 390 | ||

| N33H | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥17 | ≥1350 | 35 | 31 | 279 | 247 | H | ≤120 |

| N35H | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥17 | ≥1350 | 37 | 33 | 295 | 263 | ||

| N38H | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥17 | ≥1350 | 39 | 36 | 310 | 287 | ||

| N40H | ≥12.7 | ≥1.27 | ≥11.5 | ≥916 | ≥17 | ≥1350 | 41 | 38 | 327 | 302 | ||

| N42H | ≥13.0 | ≥1.30 | ≥11.8 | ≥940 | ≥17 | ≥1350 | 43 | 40 | 343 | 320 | ||

| N45H | ≥13.3 | ≥1.33 | ≥12.0 | ≥955 | ≥17 | ≥1350 | 46 | 42 | 366 | 335 | ||

| N48H | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥17 | ≥1350 | 49 | 45 | 390 | 358 | ||

| N50H | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 51 | 47 | 406 | 374 | ||

| N52H | ≥14.3 | ≥1.43 | ≥12.5 | ≥995 | ≥17 | ≥1350 | 53 | 49 | 422 | 390 | ||

| N33SH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥20 | ≥1592 | 35 | 31 | 279 | 247 | SH | ≤150 |

| N35SH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥20 | ≥1592 | 37 | 33 | 295 | 263 | ||

| N38SH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 39 | 36 | 310 | 287 | ||

| N40SH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥20 | ≥1592 | 41 | 38 | 327 | 302 | ||

| N42SH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥20 | ≥1592 | 43 | 40 | 343 | 320 | ||

| N45SH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥20 | ≥1592 | 46 | 42 | 366 | 335 | ||

| N48SH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥20 | ≥1592 | 49 | 45 | 390 | 358 | ||

| N50SH | ≥14 | ≥1.4 | ≥12.5 | ≥995 | ≥20 | ≥1592 | 51 | 47 | 406 | 374 | ||

| N33UH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥25 | ≥1990 | 35 | 31 | 279 | 247 | UH | ≤180 |

| N35UH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 37 | 33 | 295 | 263 | ||

| N38UH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 39 | 36 | 310 | 287 | ||

| N40UH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥25 | ≥1990 | 41 | 38 | 327 | 302 | ||

| N42UH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥25 | ≥1990 | 43 | 40 | 343 | 320 | ||

| N45UH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥25 | ≥1990 | 46 | 42 | 366 | 335 | ||

| N48UH | ≥13.6 | ≥1.36 | ≥12.2 | ≥971 | ≥25 | ≥1990 | 49 | 45 | 390 | 358 | ||

| N28EH | ≥10.4 | ≥1.04 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 30 | 26 | 239 | 207 | EH | ≤200 |

| N30EH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥30 | ≥2388 | 32 | 28 | 255 | 223 | ||

| N33EH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥30 | ≥2388 | 35 | 31 | 279 | 247 | ||

| N35EH | ≥11.8 | ≥1.18 | ≥10.8 | ≥860 | ≥30 | ≥2388 | 37 | 33 | 295 | 263 | ||

| N38EH | ≥12.3 | ≥1.23 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 39 | 36 | 310 | 287 | ||

| N40EH | ≥12.6 | ≥1.26 | ≥11.5 | ≥916 | ≥30 | ≥2388 | 41 | 38 | 327 | 302 | ||

| N42EH | ≥12.9 | ≥1.29 | ≥11.8 | ≥940 | ≥30 | ≥2388 | 43 | 41 | 343 | 320 | ||

| N45EH | ≥13.2 | ≥1.32 | ≥12.0 | ≥955 | ≥30 | ≥2388 | 46 | 42 | 366 | 335 | ||

| N30TH | ≥10.8 | ≥1.08 | ≥9.50 | ≥756 | ≥35 | ≥2786 | 32 | 28 | 255 | 223 | TH | ≤220 |

| N33TH | ≥11.4 | ≥1.14 | ≥10.6 | ≥844 | ≥35 | ≥2786 | 35 | 31 | 279 | 247 | ||

| N35TH | ≥11.8 | ≥1.18 | ≥11.0 | ≥876 | ≥35 | ≥2786 | 37 | 33 | 295 | 263 | ||

| N38TH | ≥12.2 | ≥1.22 | ≥11.0 | ≥876 | ≥33 | ≥2627 | 39 | 36 | 310 | 287 | ||

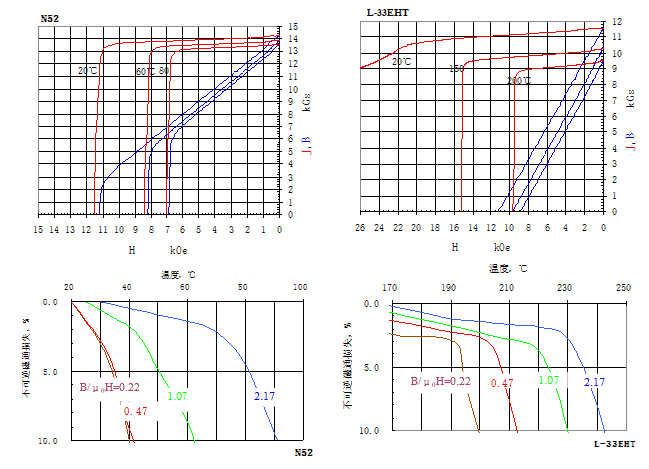

1. The magnetic parameters mentioned above are provided at room temperature.

2. The grades mentioned above are our base grades, with additional T-series (e.g., 35SHT, etc.) and L-T series (e.g., L-38SHT, etc.) derived from these base grades. The properties of the derived grades correspond to those of the base grades.

3. The maximum working temperature for our permanent magnets is determined by subjecting a sampling specification (Permanent Magnet: φ10×7) to long-term heating (typically 1000 hours) to regular temperature, followed by cooling to room temperature. The irreversible loss of magnetic flux is less than 5%. This maximum temperature is indicated by “Tw” and measured in K or ℃, and is specific to the permanent magnet material.

The maximum working temperature of our magnets can vary depending on the grade, operating conditions, coating, and environmental factors.

| Temp.Coeff.of Br | -0.11%/ °C | Temp.Coeff.of Hc | -0.60%/ °C |

| Density | 7.3-7.5g/cm 3 | Electrical Resistivity | 114 .cm |

| Vickers Hardness | 600Hv | Flexural Resistivity | 25kg/mm |

| Tensile Strength | 8.0Kg/mm2 | Coeff. Of Thermal Expansion | 4X10 -6 / °C |

| Specific Heat | 0.12Kcal/Kg | Thermal Conductivity | 7.7kcal/[m.h. °C |

| Young’s Modulus | 1.6X10[11]N/m2 | Rigidity | 0.64N/m2 |

| Poisson’s Ratio | 0.24 | Compressibility | 9.8×10-12m2/N |

| Curie Temperature | 310-340 °C |

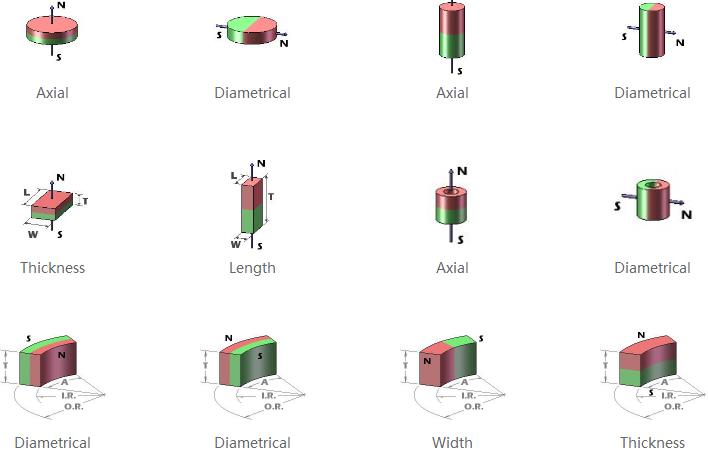

Magnetization direction refers to the direction in which the magnetic field is oriented in a magnet. For neodymium magnets, there are two main types of magnetization directions: axial and diametrical.

Axial magnetization refers to the orientation of the magnetic field along the length of the magnet. This is the most common type of magnetization direction for neodymium magnets. Axially magnetized neodymium magnets are ideal for applications that require a strong, focused magnetic field in a specific direction.

Diametrical magnetization, on the other hand, refers to the orientation of the magnetic field along the diameter of the magnet. In this type of magnetization, the magnetic poles are located on opposite sides of the magnet. Diametrically magnetized neodymium magnets are used in applications that require a broader, more diffuse magnetic field.

It is essential to understand the magnetization direction of neodymium magnets when choosing the right magnet for your application. Different magnetization directions have different effects on the magnet’s magnetic field, which can impact its performance and effectiveness.

At our manufacturing facility, we can produce neodymium magnets with both axial and diametrical magnetization directions to meet your specific needs. Contact us today to learn more about our neodymium magnets and magnetization services.

As a top supplier of magnetic materials, Sinoneo is continuously conducting research and development to ensure that they provide its customers with exceptional quality products. In pursuit of this goal, Sinoneo has recently updated its surface protection technology to provide advanced coatings and plating options, including Zinc, Tin, Nickel, and Epoxy.

Sinoneo’s advanced coatings and plating services are designed to enhance the efficiency, durability, and corrosion resistance of its magnetic materials. The company’s surface protection technology ensures that the coatings and plating are applied with precision and accuracy.

Sinoneo is also highly committed to environmental protection throughout the entire coating and plating process. All coatings used in the production of its magnetic materials are fully compliant with the requirements of ROHS and RECH.

With its industry-leading surface protection technology, Sinoneo is capable of delivering magnetic materials of exceptional quality that are widely used in various sectors such as automotive, medical, telecommunications, and renewable energy.

In conclusion, our advanced surface protection technology is the perfect solution for customers looking to acquire high-quality magnetic materials with superior protection. Contact Sinoneo today to learn more about their innovative magnetic materials and coatings

| Coating | Code | Color | Minimum Local Thickness | Memrge etching time | Working temperature | |||

| Neutralsalt Spray test | Humid heat test | Pressure Vessel test | ||||||

| Ni(Barrel plating) | Ni | Sliver | 10 | 24 | 300 | 48 | <200 | |

| Ni(rack plating) | Ni | Sliver | 10 | 8 | 300 | 48 | ||

| NiCuNi(barrel plating) | NiCuNi | Sliver | 10 | 72 | 500 | 48 | ||

| NiCuNi(rack plating) | NiCuNi | Sliver | 10 | 48 | 500 | 48 | ||

| Zinc | White zinc | Zn | White Zinc | 4 | 24 | 48 | / | <170 |

| Color zinc | CZn/Zn | Color Zinc | 6 | 48 | 48 | / | ||

| Chemical plating Ni | Ni | Silver | 12 | 96 | 500 | 48 | <200 | |

| Electrophoresis epoxy | Epoxy | Black,grey | 10 | 48-96 | 120 | 0-24 | <130 | |

| Parylene | Parylene | Colorless and transparent | 12.7-25.4 microns Meet the MIL-I-46058C standard | 48 | / | / | <130 | |

HAVEN’T FIND WHAT ARE YOU LOOKING FOR?

If you have not yet found what you are looking for then you can simply click “CONTACT US” for expert technical advice.Sinoneo is the professional sintered neodymium magnets manufacturer and supplier in China. Our magnet engineers will help you get exactly what you need – for your retail or industrial applications – in a short time with high quality at a better price.

FEATURED TYPE OF SINTERED NEO MAGNETS

GET YOUR CUSTOM neodymium MAGNETS TODAY!

NEODYMIUM ARC MAGNETS

Neodymium Arc Magnets or Neodymium Tile Magnets is one popular shape of Rare earth magnets and permanent magnets. It is always manufactured via Wire Cutting and grinding etc.

NEODYMIUM BLOCK MAGNETS

Neodymium Block Magnets is one regular shape of Rare earth magnets and permanent magnets. It is always manufactured via Cutting and grinding etc.

NEODYMIUM COUNTERSUNK MAGNETS

Neodymium Countersunk Magnets and Counterbored Magnets. Great for many applications including door/cabinet closures, hanging art on a wall, and more!

NEODYMIUM CYLINDER MAGNETS

Neodymium Cylinder magnets or NdFeB round Magnets is one basic shape of Rare earth magnets and permanent magnets. It is always manufactured via Cutting, Slicing, Centerless grinding, etc.

NEODYMIUM DISC MAGNETS

Neodymium disc magnets or round NdFeB Magnets is one basic shape of Rare earth magnets and permanent magnets. It has the following important factors such as Diameter and Thickness.

NEODYMIUM RING(TUBE) MAGNETS

Ring neodymium magnets or NdFeB Tube Magnets is one basic shape of Permanent Rare earth magnets. It has important factors such as Out Diameter, Inner Diameter, and Thickness.

Maximize the efficiency of your magnetic applications with our Neodymium Magnets, providing a strong and durable magnetic force that withstands the test of time.

Faq

Read The FREQUENTLY ASKED QUESTIONS

What are the different grades of sintered NdFeB magnets available, and which one is best suited for my application?

Sintered NdFeB magnets are available in various grades, each with different magnetic properties and characteristics. The most common grades are N35, N42, N48, and N52, with increasing numbers indicating higher magnetic strength. The choice of grade depends on the specific application requirements, such as the desired holding force, operating temperature, and cost constraints.

What are the safety precautions I need to take when handling NdFeB magnets?

Sintered rare earath NdFeB magnets are powerful and can pose safety risks if handled improperly. It’s important to keep them away from pacemakers and other medical devices, as well as electronic devices that can be damaged by strong magnetic fields. When handling large or powerful magnets, use appropriate safety equipment, such as gloves and eye protection.

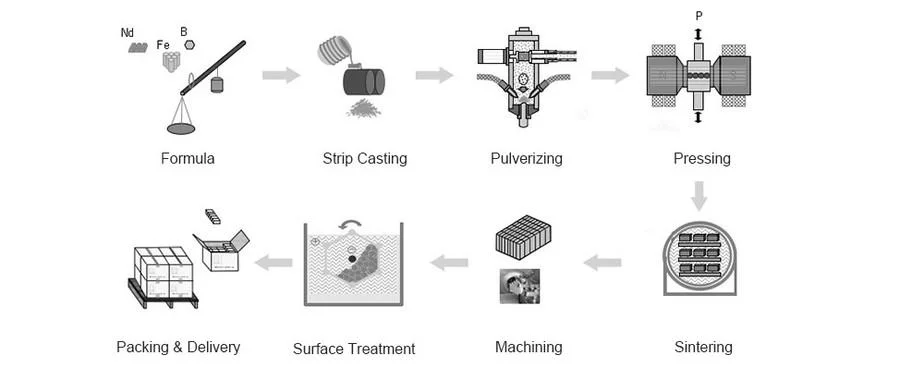

How are Sintered NdFeB Magnets Made?

Sintered NdFeB magnets are made using a powder metallurgy process. Firstly, the raw materials – neodymium, iron, and boron – are melted in a vacuum furnace and then cast into ingots. The ingots are then pulverized into a fine powder and mixed with a binding material before being compacted into the desired shape using a press. The resulting “green” magnet is then subjected to a sintering process, where it is heated to a high temperature to create a solid and dense magnet.

After sintering, the magnet is subjected to a finishing process to ensure its final properties, which includes cutting, grinding, and polishing. Finally, the magnet is coated with a protective layer to prevent corrosion and enhance its durability.

How Can I get a free custom quote?

In order to provide you with a price for our rare earth magnets (sintered NdFeB magnets), we kindly request that you provide us with the following details:

- Magnets Grade: Please specify the grade of magnet you require, ranging from N35 to N50, from N Series to UH Series.

- Magnet Size: Please provide the size requirements as per your drawing.

- Magnetization Direction: Kindly specify the orientation of the north and south poles.

- Magnets Coating: We offer a range of coating options such as Nickel, Zn, Black Epoxy, Ag, Au, etc. Please specify your preferred option.

- Quantities: We offer lower prices for larger order quantities. As an original factory, we can cater to your mass order requirements.

At our company, we are committed to delivering high-quality rare earth magnets with exceptional performance and durability. We have a wide range of sintered NdFeB magnets in various sizes and grades, suitable for a range of industries such as automotive, renewable energy, and medical equipment.

Contact us today with your requirements, and we will provide you with a competitive quote for your rare earth magnet needs. Our team is dedicated to providing superior customer service, and we are confident that we can meet and exceed your expectations.