High-Precision Magnetic Chucks: Maximum Holding Power for Complex Machining Tasks

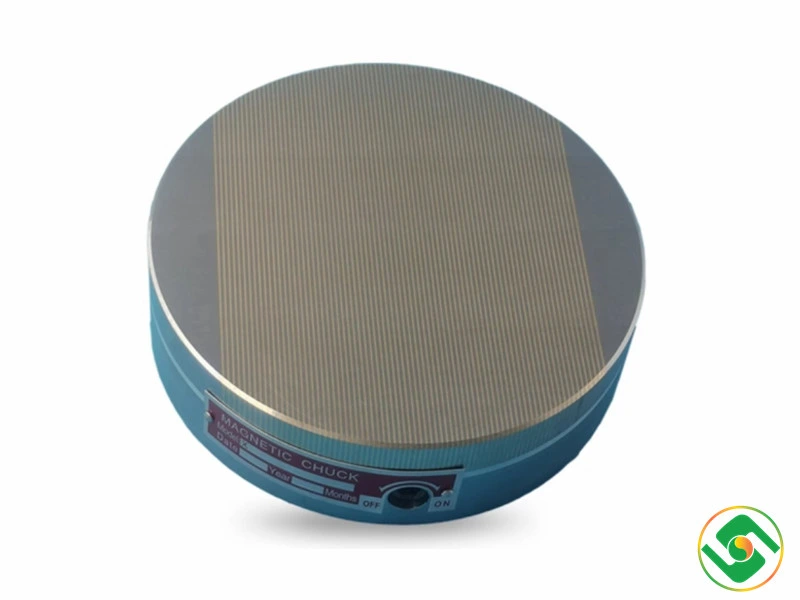

Permanent Magnetic Chuck

Permanent Magnetic chucks are an important part of various machining processes permanently installed in grinding, milling, and turning applications.

These chucks use permanent neodymium magnets to generate a powerful attractive force for the ferromagnetic components without supply of constant current.

GET A FREE QUOTE

Industrial Permanent Magnetic Chucks: Premium Workholding Solutions for Precision Grinding and Milling

High-Performance Magnetic Workholding Solutions

Upgrade your machining accuracy and choose our premium permanent magnetic chucks for grinding and milling. We have a broad range of industrial permanent magnetic workholding systems and our products are of high quality for precision metalworking requirements. This product line utilizes the latest magnetic materials and industrial engineering to offer dependable workholding solution relevant to today’s manufacturing environment.

Advanced Features for Precision Manufacturing

Professional Magnetic System

- Professional-grade permanent magnetic chuck design up to 180 N/cm² holding force

- Premium neodymium magnets material for optimal performance

- Fine-pole and standard-pole configurations for diverse applications

Industrial-Grade Construction

- High-precision ground surface finish for maximum accuracy

- Heavy-duty stainless steel construction for durability

- Waterproof design for wet grinding operations

- Precision-engineered pole spacing for optimal workpiece holding

Applications in Modern Manufacturing

Precision Grinding Operations

- Surface grinding magnetic chuck solutions

- Double-disk grinding workholding systems

- CNC grinding machine magnetic workholding

- Precision profile grinding applications

Milling and Metalworking

- Industrial milling machine magnetic chucks

- Custom magnetic workholding fixtures

- Metal fabrication magnetic systems

- Tool and die manufacturing solutions

Key Benefits for Manufacturing Excellence

- Zero power consumption during operation

- Rapid workpiece setup and changeover

- Uniform holding force distribution

- Minimal maintenance requirements

- Enhanced workshop productivity

All of our magnetic chuck systems include full technical support and are provided with a one year warranty to give you peace of mind.

Every single unit produced goes through rigorous quality tests that affirm to safety standards of major world markets.

Get in touch with our technical support team now to find out how our magnetic chuck services can benefit you. Each service we provide can be adapted to the needs of a particular application and guarantee the high efficiency and profitability of its use.

The Common Specifications Of Rectangular Permanent Magnetic Chuck

| TYPE | B | L1 | H | P=P1+P2 | N.W | package demision | G.W | REMARKS | |

| (mm) | (mm) | (mm) | (mm) | N.(kg) | M.(cm) | W.(kg) | |||

| MCS1018 | 104 | 180 | 43 | 0.5+1.5 | 6.5 | 26X16X8 | 9.5 | H=43-60 , L1=150-350 | Magnetic Force: 12kgf/cm2,It also can produce as your request. |

| MCS1018 | 104 | 180 | 43 | 1+3 | 6.5 | 26X16X8 | 9.5 | ||

| MCS1018 | 104 | 180 | 43 | 2+4 | 6.5 | 26X16X8 | 9.5 | ||

| MCS1225 | 120 | 250 | 43 | 0.5+1.5 | 10.5 | 33X18X8 | 15 | H=43-60 , L1=150-450 | |

| MCS1225 | 120 | 250 | 43 | 1+3 | 10.5 | 33X18X8 | 15 | ||

| MCS1225 | 120 | 250 | 43 | 2+4 | 10.5 | 33X18X8 | 15 | ||

| MCS1235 | 120 | 350 | 50 | 0.5+1.5 | 16.5 | 43X18X9 | 20 | ||

| MCS1235 | 120 | 350 | 50 | 1+3 | 16.5 | 43X18X9 | 20 | ||

| MCS1235 | 120 | 350 | 50 | 2+4 | 16.5 | 43X18X9 | 20 | ||

| MCS1530 | 150 | 300 | 43 | 0.5+1.5 | 15.5 | 38X21X8 | 19 | H=43-60 , L1=300-600 | |

| MCS1530 | 150 | 300 | 43 | 1+3 | 15.5 | 38X21X8 | 19 | ||

| MCS1530 | 150 | 300 | 43 | 2+4 | 15.5 | 38X21X8 | 19 | ||

| MCS1535 | 150 | 350 | 43 | 0.5+1.5 | 18.5 | 43X21X8 | 22 | ||

| MCS1535 | 150 | 350 | 43 | 1+3 | 18.5 | 43X21X8 | 22 | ||

| MCS1535 | 150 | 350 | 43 | 2+4 | 18.5 | 43X21X8 | 22 | ||

| MCS2040 | 200 | 400 | 50 | 0.5+1.5 | 32 | 48X26X9 | 38 | H=43-60 , L1=300-700 | |

| MCS2040 | 200 | 400 | 50 | 1+3 | 32 | 48X26X9 | 38 | ||

| MCS2040 | 200 | 400 | 50 | 2+4 | 32 | 48X26X9 | 38 | ||

| MCS2050 | 200 | 500 | 50 | 0.5+1.5 | 40 | 58X26X9 | 47 | ||

| MCS2050 | 200 | 500 | 50 | 1+3 | 40 | 58X26X9 | 47 | ||

| MCS2050 | 200 | 500 | 50 | 2+4 | 40 | 58X26X9 | 47 | ||

| MCS2550 | 250 | 500 | 50 | 0.5+1.5 | 50 | 58X31X9 | 58 | H=50-65 , L1=400-700 | |

| MCS2550 | 250 | 500 | 50 | 1+3 | 50 | 58X31X9 | 58 | ||

| MCS2550 | 250 | 500 | 50 | 2+4 | 50 | 58X31X9 | 58 | ||

| MCS2565 | 250 | 650 | 50 | 0.5+1.5 | 65 | 73X31X9 | 73 | ||

| MCS2565 | 250 | 650 | 50 | 1+3 | 65 | 73X31X9 | 73 | ||

| MCS2565 | 250 | 650 | 50 | 2+4 | 65 | 73X31X9 | 73 | ||

| MCS3060 | 300 | 600 | 50 | 0.5+1.5 | 72 | 68X36X9 | 82 | H=50-65 , L1=450-700 | |

| MCS3060 | 300 | 600 | 50 | 1+3 | 72 | 68X36X9 | 82 | ||

| MCS3060 | 300 | 600 | 50 | 2+4 | 72 | 68X36X9 | 82 | ||

Suction : 8kgf/cm2 , 10kgf/ cm2 , 12kgf/ cm2 (Specific made as order)

The permanent-magnetic chuck is applied to holding workpiece of magnetic material to begroud on surface grinding machine and universal tool grinder electrical process machine ect. And can also be used as line-drawing tools of benchwork for scraping and grinding .

The permanent-magnetic chuck doesn’t need power supply and wil not cause any unexpected accident because of fallure of power supply , therefore , it is being widely used.

The Common Specifications Of Round Permanent Magnctic Chuck

Considerations When Choosing a Permanent Magnetic Chuck

Clamping Force

The success of a chuck is sometimes defined by the clamping force it makes. For example our Neox permanent chuck has clamping force that can reach 180 N/cm², it is designed for turning and grinding round shaped workpieces.

Workpiece Size and Shape

Different chucks are created to embrace different kinds of shapes and sizes of the workpieces to be machined. Fine pitch chucks are highly suitable for the small and thin work piece but can also grip substantial works depending upon the cutter used.

Frequently Asked Questions (FAQ)

Q1: What is the difference between permanent magnetic chucks and electromagnetic chucks?

A: Permanent magnetic chucks use high-strength permanent magnets and require no continuous power supply, offering consistent holding force without electricity consumption. They are more energy-efficient and maintenance-free compared to electromagnetic systems that need constant power input.

Q2: What is the maximum holding force of your permanent magnetic chucks?

A: Our permanent magnetic chucks provide a holding force up to 180 N/cm². The actual holding force may vary depending on the workpiece material, surface condition, and contact area. Our technical team can help determine the optimal configuration for your specific application.

Q3: Can permanent magnetic chucks be used for wet grinding operations?

A: Yes, our permanent magnetic chucks feature IP67-rated waterproof construction, making them ideal for wet grinding applications. The sealed design prevents coolant infiltration and ensures reliable performance in wet machining environments.

Q4: What materials can be held by permanent magnetic chucks?

A: Permanent magnetic chucks are designed to hold ferromagnetic materials such as steel, iron, and nickel alloys. The holding force depends on the material’s magnetic permeability and carbon content. Non-ferrous materials like aluminum, brass, or stainless steel (depending on grade) may require additional fixturing solutions.

Q5: How long does the magnetic force last in a permanent magnetic chuck?

A: Our permanent magnetic chucks are designed to maintain their magnetic force for decades with proper use and maintenance. The high-quality magnetic materials used in construction ensure minimal force degradation over time. Regular inspection and proper handling will help maintain optimal performance throughout the chuck’s lifetime.