Rotary Vibrating Screen: The Ultimate Multi-Layer Screening Solution for Industrial Applications

Rotary Vibrating Screen

The three-dimensional vibrating screen is a high-precision fine powder screening machine. It features low noise, high efficiency, and quick screen replacement (taking only 3-5 minutes). With its fully enclosed structure, it is suitable for screening and filtering granular, powdery, and viscous materials.

Available on backorder

GET A FREE QUOTE

What is a Rotary Vibrating Screen?

A rotary vibrating screen (also known as a three-dimensional vibrating screen or circular vibrating screen) is a high-efficiency, precision industrial screening equipment designed for fine particle separation across multiple industries. This advanced screening technology utilizes vertical vibrating motors to create three-dimensional material movement, delivering superior screening performance compared to traditional linear vibrating screens.

Key Features & Advantages

1. High-Efficiency Screening with Maximum Throughput

- 30-50% higher processing capacity than conventional vibrating screens

- Vertical vibrating motor creates three-dimensional jumping motion for faster material penetration

- Ideal for fine powders (flour, starch, metal powders) and small particles (grains, additives)

- Continuous operation capability for 24/7 production environments

2. Precision Multi-Layer Classification

- 1-5 screening layers in standard models

- Simultaneously separates materials into 2-6 different particle sizes

- Wide mesh range: 20-500 mesh (0.028mm precision)

- Perfect for applications requiring multiple grade separations (30, 60, 100 mesh simultaneously)

3. Dust-Free Environmental Protection

- Fully enclosed structure with silicone sealing rings

- Meets GMP and food-grade production standards

- Optional negative pressure dust removal interface

- Eliminates powder flying and contamination risks

4. Anti-Clogging Design with Easy Maintenance

- Bouncing ball cleaning system (rubber/silicone balls) prevents mesh blockage

- Quick-release screen design – mesh replacement in just 3-5 minutes

- Minimizes downtime and maximizes productivity

- Self-cleaning mechanism reduces manual maintenance

5. Energy-Efficient & Durable Operation

- Low power consumption (0.25-3kW) – 20% more energy-efficient than traditional screens

- Rubber spring damping system reduces noise below 75 decibels

- 8-10 year equipment lifespan with proper maintenance

- Stable operation with minimal vibration transfer

6. Customizable Solutions for Specific Applications

- 304 stainless steel construction for food/pharmaceutical applications

- Carbon steel with powder coating for chemical/metallurgical use

- Optional ultrasonic anti-clogging system for difficult materials

- Explosion-proof motors available for hazardous environments

Why Choose Our Rotary Vibrating Screen?

Superior Performance

- Proven technology with thousands of successful installations worldwide

- Higher screening efficiency translates to increased productivity and reduced operating costs

- Consistent particle size distribution ensures product quality

Reliable Operation

- Robust construction designed for continuous industrial use

- Easy maintenance minimizes downtime and service costs

- Long service life provides excellent return on investment

Versatile Applications

- Multi-industry compatibility from food processing to heavy chemicals

- Customizable configurations to meet specific application requirements

- Scalable solutions for both small-scale and large-scale operations

Quality Assurance

- ISO certification ensures manufacturing quality

- Comprehensive warranty and after-sales support

- Professional installation and training services available

Industrial Applications

Chemical Industry

- Resins, coatings, industrial chemicals, cosmetics

- Paints, traditional Chinese medicine powders

- Polymer powders, catalysts, pigments

Food & Beverage Industry

- Sugar powder, starch, food salt, rice flour

- Milk powder, soy milk powder, egg powder

- Soy sauce, fruit juice, spice powders

- Cocoa powder, coffee grounds, tea leaves

Metallurgy & Mining

- Aluminum powder, copper powder, ore materials

- Alloy powders, welding electrode powders

- Manganese dioxide, electrolytic copper powder

- Magnetic materials, abrasive powders, refractory materials

Other Industries

- Waste oil treatment, wastewater processing

- Dyeing wastewater, papermaking additives

- Activated carbon, ceramic materials

- Pharmaceutical intermediates, fine chemicals

Technical Specifications

| Parameter | Range | Details |

|---|---|---|

| Screening Layers | 1-5 layers | Up to 6 different particle sizes |

| Mesh Range | 20-500 mesh | 0.028mm minimum separation |

| Power Range | 0.25-3kW | Energy-efficient operation |

| Noise Level | <75 dB | Quiet operation |

| Material Options | SS304/Carbon Steel | Application-specific construction |

| Capacity | Variable | 30-50% higher than conventional screens |

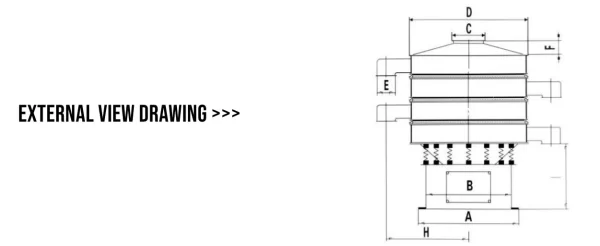

| Model | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | H (mm) | I (mm) | Single Layer Height (mm) | Double Layer Height (mm) | Triple Layer Height (mm) |

| RVS-400 | 330 | 305 | 200 | 400 | 80 | 70 | 320 | 390 | 670 | 770 | 870 |

| RVS-600 | 530 | 430 | 250 | 600 | 100 | 70 | 430 | 415 | 740 | 850 | 960 |

| RVS-800 | 680 | 580 | 250 | 800 | 125 | 90 | 540 | 415 | 850 | 980 | 1100 |

| RVS-1000 | 800 | 700 | 250 | 970 | 150 | 100 | 643 | 415 | 850 | 980 | 1100 |

| RVS-1200 | 985 | 855 | 400 | 1170 | 180 | 120 | 750 | 540 | 955 | 1100 | 1245 |

| RVS-1500 | 1190 | 1050 | 400 | 1470 | 200 | 120 | 930 | 560 | 1000 | 1145 | 1290 |

| RVS-1800 | 1540 | 1440 | 400 | 1770 | 200 | 120 | 1025 | 680 | 1250 | 1400 | 1550 |

| RVS-2000 | 1800 | 1720 | 600 | 1960 | 200 | 170 | 1260 | 680 | 1250 | 1400 | 1550 |

Frequently Asked Questions (FAQ)

Q1: How does a rotary vibrating screen work?

A: The rotary vibrating screen uses a vertical vibrating motor to generate three-dimensional circular motion. Materials are fed from the top and move in a spiral pattern across multiple screening layers, with particles separated by size through different mesh screens.

Q2: What’s the maximum number of screening layers available?

A: Standard models support 1-5 screening layers, allowing simultaneous separation into 2-6 different particle sizes. While up to 5 layers are possible, we recommend using 3 layers for optimal performance.

Q3: How fine can the screening go?

A: Our rotary vibrating screens can achieve screening precision up to 500 mesh (0.028mm), making them suitable for ultra-fine powder separation applications.

Q4: How long does screen mesh replacement take?

A: The quick-release design allows screen mesh replacement in just 3-5 minutes, significantly reducing downtime compared to traditional screening equipment.

Q5: Is the equipment suitable for food-grade applications?

A: Yes, we offer 304 stainless steel construction with GMP-compliant design, making it perfect for food, pharmaceutical, and other hygiene-sensitive applications.

Q6: What maintenance is required?

A: Routine maintenance includes periodic cleaning, rubber ball replacement, and mesh inspection. The anti-clogging bouncing ball system significantly reduces maintenance frequency.

Q7: How energy-efficient is the rotary vibrating screen?

A: Our screens consume 20% less energy than traditional vibrating screens, with power consumption ranging from 0.25-3kW depending on model and application.

Q8: Can it handle sticky or difficult materials?

A: Yes, optional ultrasonic anti-clogging systems are available for challenging materials like sticky powders, high-static materials, or moisture-sensitive products.

Q9: What’s the expected equipment lifespan?

A: With proper maintenance, our rotary vibrating screens typically last 8-10 years, providing excellent return on investment.

Q10: Do you provide installation and training services?

A: Yes, we offer comprehensive installation, commissioning, and operator training services to ensure optimal equipment performance from day one.

Get a Customized Solution For Your Project

Transform your screening operations with our high-performance rotary vibrating screens. Whether you’re processing fine powders, granular materials, or liquids, our customizable solutions deliver the precision and efficiency your operation demands.

Contact us now for:

- Free application consultation

- Custom equipment sizing

- Competitive pricing

- Technical support and training

Ready to upgrade your screening process? Request a quote today and discover why thousands of companies worldwide trust our rotary vibrating screen technology.

Related products

-

Sale!

Linear Vibrating Screen Sieve Machine

$3,000.00Original price was: $3,000.00.$2,500.00Current price is: $2,500.00. -

Easy Clean Magnetic Grids

$50.00 -

Sale!

tumbler screen machine

$5,000.00Original price was: $5,000.00.$4,500.00Current price is: $4,500.00. -

Square Magnetic Grills

$50.00 -

Magnetic Grate Separator

$50.00 -

Magnetic Grates and Grids

$50.00 -

Round Magnetic Grills

$50.00 -

Magnetic Grate with angular baffles

$100.00

We’ve Been Working For Over 10 Years

As a leader in magnetic technology, we are constantly innovating to meet the evolving needs of our customers. In response to the increasing demand for efficient powder processing solutions, we are proud to introduce our new line of Powder Sieving Equipment, including vibrating screens, swing screens, and screw conveyors. This expansion allows us to offer a complete, integrated solution that combines magnetic separation and screening to enhance product purity, streamline production, and optimize your processing lines.