Ultrasonic Vibrating Screen: Advanced Screening Technology for Fine Particle Separation

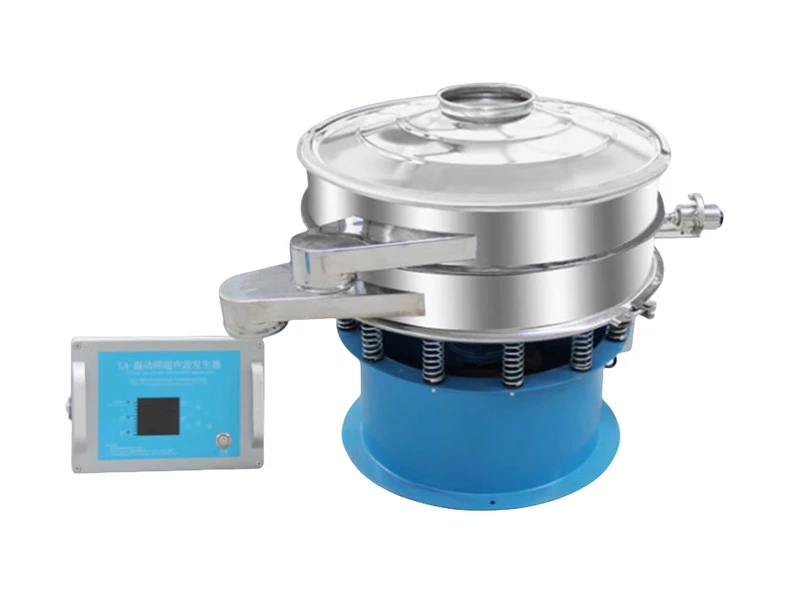

ultrasonic vibrating screen machine

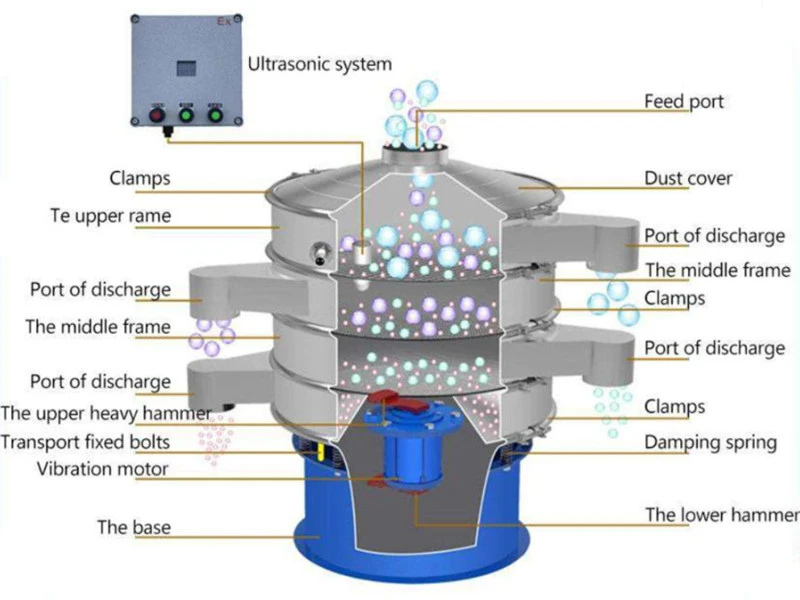

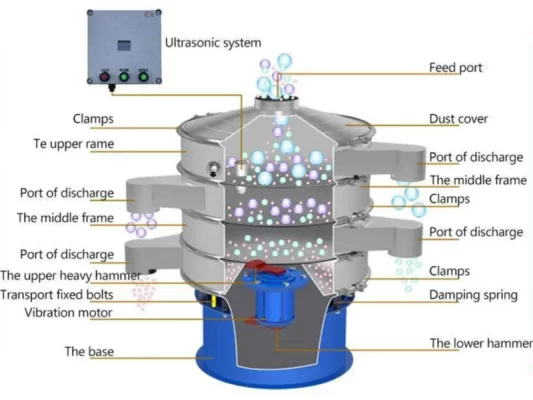

The Ultrasonic Vibrating Screen is a high-performance sieving solution designed for precise separation and deblinding of fine powders. By combining an ultrasonic generator with a mesh frame, the system creates high-frequency vibrations on the screen surface. These vibrations prevent mesh clogging, boost throughput, and ensure a more refined and accurate screening process—ideal for ultra-fine materials and complex particles.

GET A FREE QUOTE

🚫 Tired of Screen Clogging and Low Screening Efficiency?

If your production line is constantly interrupted by mesh blinding, inconsistent particle separation, or low throughput—especially when dealing with fine powder, sticky particles, or ultrafine materials—you’re not alone.

Traditional vibrating sieves often fall short when it comes to high-precision screening.

But that changes now.

Introducing the Ultrasonic Vibrating Screen – your ultimate solution for anti-clogging fine powder screening, designed to deliver up to 10x higher efficiency and dramatically improve screening accuracy.

✅ What Is an Ultrasonic Vibrating Screen?

The Ultrasonic Vibrating Screen is an advanced sieving machine that integrates an ultrasonic generator with a vibration mesh frame. The result? High-frequency vibrations (up to 36,000 times per second) that keep the mesh surface clear, prevent clogging, and maintain consistent powder flow across even the finest mesh sizes (as fine as 635 mesh).

It’s specifically engineered for fine powder separation, difficult-to-screen materials, and high-demand industrial environments.

🔍 Key Benefits at a Glance

✔ Anti-clogging, anti-static performance

No more bouncing balls, brushing, or downtime. The ultrasonic system keeps powders moving freely through the mesh.

✔ Extended mesh life

Reduce wear and tear on screens by eliminating the friction caused by stuck particles and mechanical bouncing devices.

✔ High throughput – up to 10x more

Faster screening cycles mean higher daily output, improved yield, and lower operating cost per ton.

✔ Designed for ultra-fine powder

Especially effective for 100 mesh and below, where traditional sieves struggle most.

✔ Handles sticky, light, or fibrous materials

From electromagnetic powder to TMP, laser powder, or coffee grounds, this screen handles them all with precision.

🏭 Industries Using Ultrasonic Vibrating Screens

This technology is already trusted by companies in:

Metal Powder Processing (e.g., tungsten, molybdenum, stainless steel powder)

Battery Material Manufacturing (e.g., anode/cathode powder, electromagnetic materials)

Chemical & Coating Production (e.g., TMP, powder coatings)

Food & Beverage (e.g., coffee powder, flour, tea powders)

Abrasives & Minerals (e.g., silicon carbide, quartz)

Pharmaceuticals (e.g., fine APIs, excipients)

Wherever fine powder sieving is critical to product quality and operational efficiency, the ultrasonic sieve separator proves its value.

🧪 Why It Works Better

Here’s the science:

Traditional screens vibrate at low mechanical frequencies (15–60 Hz), which work fine for large particles. But with ultra-fine or sticky powders, particles stick to the mesh or bridge across openings.

Our ultrasonic vibrating system introduces high-frequency micro-vibrations (above 30 kHz) through the mesh. This:

Disrupts surface tension between particles and mesh

Loosens particles stuck in screen holes

Prevents “screen blinding” without needing bouncing balls

That means you screen faster, cleaner, and longer — without sacrificing yield or mesh integrity.

📦 Customization Available

We understand no two production lines are the same. That’s why we offer:

Custom mesh sizes, screen diameters, and layer numbers

Pharma-grade or food-grade designs

Multi-deck configuration for multi-stage screening

Explosion-proof or sealed units for sensitive materials

Integration support for existing systems

⚙️ Technical Specifications

Ultrasonic System Parameters:

- Frequency Range: 20-40 kHz optimized for fine particle screening

- Ultrasonic Power: 50-200W per transducer

- Transducer Configuration: Multi-point distribution for uniform coverage

- Resonance Control: Automatic frequency adjustment for optimal performance

Screen Capabilities:

- Mesh Range: 40-635 mesh (ultrasonic mesh screen specialty)

- Fine Mesh Excellence: 100-635 mesh applications

- Screen Diameter: 400-3000mm available

- Screen Materials: Stainless steel, polyurethane, nylon options

Performance Guarantees:

- Screening Efficiency: Up to 99.5% separation accuracy

- Capacity Range: 100-5000 kg/hour depending on material

- Power Consumption: 1.5-15 kW (30% less than conventional)

- Operating Temperature: -20°C to 80°C continuous operation

Industries Dominating with Our Technology:

- Battery material screening equipment manufacturers

- Pharmaceutical powder screening facilities

- Metal powder screening system operations

- Ceramic powder classification plants

- Silicon carbide powder screening applications

- Food grade ultrasonic screening processors

Why Choose Our Ultrasonic Screening Technology:

- Anti-clogging screen technology eliminates production shutdowns

- High-frequency vibration technology ensures consistent performance

- Ultrasonic transducer screening handles the most challenging materials

- Fine mesh vibrating screen solution for demanding applications

- Ultrasonic sieving machine reliability you can count on

Don’t wait – call now and join the screening revolution!

✅ Common Specifications

| Model | Layers | Granularity (mm) | Screening Area (㎡) | Sieve Mesh | Effective Diameter (mm) | Power (KW) |

|---|---|---|---|---|---|---|

| UVS400 | 1–3 | <20 | 0.1 | 20–600 mesh | 380 | 0.25 |

| UVS600 | 1–3 | <20 | 0.23 | 20–600 mesh | 580 | 0.55 |

| UVS800 | 1–5 | <30 | 0.41 | 20–600 mesh | 780 | 0.75 |

| UVS1000 | 1–5 | <30 | 0.65 | 20–600 mesh | 970 | 1.1 |

| UVS1200 | 1–5 | <30 | 0.99 | 20–600 mesh | 1170 | 1.5 |

| UVS1500 | 1–5 | <50 | 1.58 | 20–600 mesh | 1470 | 2.2 |

| UVS1800 | 1–5 | <50 | 2.32 | 20–600 mesh | 1770 | 3.0 |

💬 What Our Customers Say

The switch to ultrasonic screening changed everything. Zero clogging. Better cut. Less waste. And our mesh life doubled.”

— Powder Coatings Manufacturer, South Asia“We struggled with 325 mesh stainless steel powder until we tried this system. It now runs 24/7 without failure.”

— Additive Manufacturing Facility, EU

❓Frequently Asked Questions(FAQ)

Technical Questions Engineering Teams Ask

Q: How does ultrasonic technology prevent clogging?

A: The high-frequency vibration technology (20-40 kHz) creates micro-movements that prevent particle agglomeration and break up forming clogs before they can block screen openings.

Q: What mesh sizes can you handle?

A: Our ultrasonic screening system handles 40-635 mesh applications, with particular expertise in fine mesh vibrating screen operations (100+ mesh) where traditional screens fail.

Q: How does maintenance compare to conventional screens?

A: Maintenance is reduced by approximately 70% because the anti-clogging vibrating screen eliminates the need for bouncing balls, frequent cleaning, and premature mesh replacement.

Q: Can it handle abrasive materials?

A: Yes, the gentle ultrasonic vibrations actually reduce wear on screen surfaces while improving separation efficiency. Perfect for silicon carbide powder screening and other abrasive applications.

Q: What about food and pharmaceutical applications?

A: Our food grade ultrasonic screening systems meet all FDA and cGMP requirements. The contamination-free design is ideal for pharmaceutical powder screening applications.

Business Questions Managers Ask

Q: What’s the typical payback period?

A: Most customers achieve complete ROI within 12-18 months through reduced maintenance costs, increased throughput, and improved quality. Many see payback in under 10 months.

Q: How reliable is this technology?

A: Our ultrasonic screening equipment has been proven in over 500 installations worldwide. The system includes comprehensive monitoring and automatic adjustment capabilities.

Q: What support do you provide?

A: Complete support includes 24/7 technical hotline, on-site service, operator training, and guaranteed spare parts availability. We’re your long-term technology partner.

Q: Can it integrate with our existing systems?

A: Yes, our ultrasonic vibrating screen is designed for easy integration. Most installations require minimal modifications to existing conveyor and collection systems.

🔍 Get My Free Sieving Consultation

📈 Ready to Upgrade Your Screening Line?

If you’re still using mechanical-only screens for fine powders, you’re likely losing time, money, and product. The Ultrasonic Vibrating Screen offers a proven, scalable solution to:

Increase screening capacity

Improve product quality

Reduce downtime and manual cleaning

Lower total cost of ownership

Whether you need a single unit or full production line integration, we’re here to support you.

📩 Email: sales@sinoneo.com

📞 WhatsApp: +86 15906508736

🌐 Visit: www.sinoneo.com

Manufacturing companies worldwide are discovering that ultrasonic vibrating screen technology isn’t just an improvement – it’s a complete game-changer. While your competitors struggle with clogged screens and production shutdowns, you’ll be running continuously with higher quality output and lower operating costs.

The question isn’t whether you can afford this technology. The question is: Can you afford NOT to have it?

Next Steps

- Contact our technical team to discuss your specific screening challenges

- Join the growing number of companies gaining competitive advantage with ultrasonic screening

Don’t let your competition get there first. Contact us today.

This ultrasonic screening technology has been proven in over 500 installations worldwide. Join the manufacturers who choose superior performance over outdated equipment.

Related products

-

Round Magnetic Grills

$50.00 -

Magnetic Grates and Grids

$50.00 -

Sale!

tumbler screen machine

$5,000.00Original price was: $5,000.00.$4,500.00Current price is: $4,500.00. -

Sale!

Rotary Vibrating Screen

$2,000.00Original price was: $2,000.00.$1,500.00Current price is: $1,500.00. -

Easy Clean Magnetic Grids

$50.00 -

Square Magnetic Grills

$50.00 -

Sale!

Linear Vibrating Screen Sieve Machine

$3,000.00Original price was: $3,000.00.$2,500.00Current price is: $2,500.00. -

Magnetic Grate with angular baffles

$100.00

We’ve Been Working For Over 10 Years

As a leader in magnetic technology, we are constantly innovating to meet the evolving needs of our customers. In response to the increasing demand for efficient powder processing solutions, we are proud to introduce our new line of Powder Sieving Equipment, including vibrating screens, swing screens, and screw conveyors. This expansion allows us to offer a complete, integrated solution that combines magnetic separation and screening to enhance product purity, streamline production, and optimize your processing lines.